The Sanbi production region, which encompasses part of Western Okayama Prefecture and eastern Hiroshima Prefecture, is a leading denim jeans production center for Japan. Large numbers of industry players involved in dyeing, weaving, cutting, sewing, finishing and other steps of the production process are gathered in the region, which has garnered global attention from famous brand producers worldwide for its high-quality denim jeans.

The areas comprising modern-day Fukuyama City in Hiroshima Prefecture and Ibara City in Okayama Prefecture have boasted thriving cotton cultivation and weaving industries since the Edo Period (1603–1868). During the subsequent Meiji Period (1868–1912), major growth was seen in Sanbi's textile industry, which produced Bingo-gasuri dyed textiles and Bicchu Kokura-ori woven textiles, among other products. In addition, the area that now comprises Okayama's Kurashiki City has long thrived as a producer of tabi traditional socks and more contemporarily school uniforms and workwear, all rooted in local industry which revolves around Sanada-himo braided ribbons, Kokura-ori woven goods and similar products made possible through cotton cultivation dating back to the Edo Period.

As a reflection of this history, the Sanbi production region has developed rich technologies and techniques related to thick-fabric weaving, sewing, indigo dyeing and other such processes for many long years. These, in turn, have facilitated the development of sophisticated techniques required for jeans and other denim products in the fields of spinning, dyeing, weaving, sewing and beyond. Today, Sanbi is home to many companies involved in the production of denim and jeans, having evolving into a production center with technologies and techniques that garner global acclaim.

Denim is a woven fabric made using indigo-dyed warps (vertical threads which are held stationary) and undyed wefts (horizontal threads which are drawn through). There are many explanations as to the linguistic roots of the word "denim"; the most popular states that denim's first incarnation was as a serge (Western-style twill-weave fabric) made in the French town of Nîmes, referred to in French as the serge de Nîmes (serge fabric from Nîmes), which was shortened to the contraction denim. The generally accepted definition of "jeans" is trousers made from denim, and this style of pants is popular among all types of people, from young to old. In addition, denim is seeing increasing applications in products other than jeans.

Cotton balls are harvested, the cotton and seeds separated using a cotton gin, and the resulting cotton spun into thread.

A portion of the threads are dipped in dyeing vats and wrung multiple times to dye them indigo.

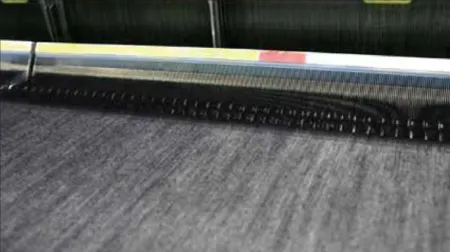

Indigo-dyed threads are wrapped around a beam to be used as the warps (woven threads), which are interwoven with the white wefts (stationary threads).

The denim fabric is coated with a finishing agent and then passed between rollers as a means of preventing shrinkage.

Following sewing of the pockets, crotch and fly seams, rivets, hems, and so forth, the trousers attain their finished form.

In order to finalize the intended look of the product, the jeans are washed, frayed, torn, adorned, dyed and/or otherwise processed.

Various denim and jeans-related events are being held in the Sanbi area. Some of them are introduced below.